|

|

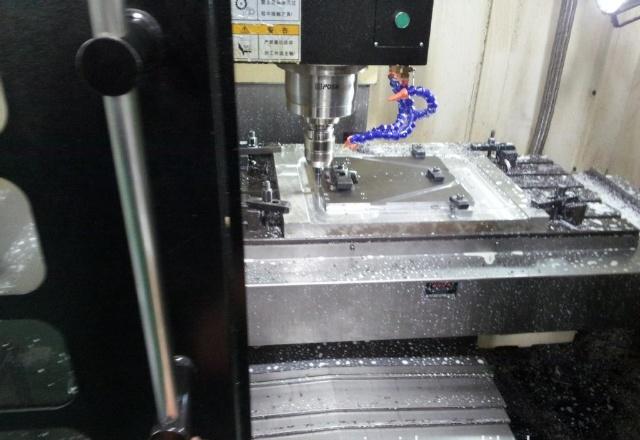

Do not understand these mechanical knowledge, you dare to say that you have learned machinery?In the process of machining, it is inevitable to use machine tool fixture. In some processing processes, a good set of suitable fixture can completely improve the processing efficiency and quality. Well, the following about the fixture and workpiece positioning knowledge, do you understand? 1、 The classification and application of machine tool fixture according to the requirements of the process specification, to ensure that the workpiece to obtain the correct position relative to the machine tool and cutter, and through clamping the workpiece to ensure that the correct position of the workpiece is always maintained in the process of processing, known as machine tool fixture. Classification of machine tool fixture: according to the different machine tools used, the fixture can be divided into lathe fixture, milling machine fixture, drilling machine fixture, grinder fixture, etc. according to the different clamping force device used on the fixture, the fixture can be divided into manual fixture, pneumatic fixture, hydraulic fixture, magnetic fixture, etc; It can be divided into general fixture, special fixture, adjustable fixture, modular fixture, etc.

1. General fixture General fixture refers to the fixture whose structure and size have been standardized and standardized, which can be used to process different workpieces in a certain range. This kind of fixture has been manufactured and supplied by machine tool accessory factory as an accessory of machine tool. The general fixture mainly includes: Center, chuck, snap ring, dial, self centering chuck (three jaw chuck), single acting chuck (four jaw chuck), transition disc, fancy disc, dividing head, flat vise for machine tool, rotary table, electromagnetic chuck, permanent magnetic chuck, milling head, plug, boring head, etc. This kind of fixture is characterized by strong adaptability, which can be used to clamp workpieces with certain shape and size range without adjustment or slight adjustment.

2. Special fixture Special fixture refers to the fixture specially designed and manufactured for a certain working procedure of a workpiece. This kind of fixture is characterized by strong pertinence, compact structure, simple operation and high productivity; its disadvantage is that the design and manufacturing cycle is long, and the fixture will be scrapped as long as the size and shape of the parts change after the product is updated.

2、 Principle and application of workpiece positioning The method to make the workpiece quickly get the correct position on the fixture is called positioning. The surface on which the workpiece is positioned is called the locating datum plane. The surface used to support the workpiece positioning datum plane on the fixture is called the support surface. The selection of datum plane should coincide with the original datum of workpiece as far as possible, so as to reduce the positioning error. The positioning of the workpiece should conform to the six point positioning principle. 1. Six point positioning principle. A free object in any space can be decomposed into six directions of motion relative to three mutually perpendicular coordinate planes, that is, the movement along the coordinate axes x 0, 0 y and O Z and the rotation around these three axes. In order to make the workpiece have a definite position in a certain direction of the fixture, the degree of freedom in that direction must be limited. In order to keep the workpiece in a stable position on the fixture, it is necessary to limit the six degrees of freedom of the workpiece. Therefore, positioning is to limit the degree of freedom. The principle of six point positioning is to select and distribute six supporting points correctly to limit the position of workpiece in the fixture.

2. Positioning requirements of workpiece. In practical work, the six degrees of freedom are not necessarily limited in the positioning of workpieces, but the number of limited degrees of freedom should be determined according to the requirements of the process, the form of positioning and the layout. ① Fully positioned. When the workpiece is positioned, its six degrees of freedom are all limited, which is called complete positioning. ② Incomplete positioning. According to the processing requirements of this process, the workpiece only needs to limit its partial degree of freedom, but does not affect the processing requirements of the process, which is called incomplete positioning. ③ Under positioning. The number of degrees of freedom limited by the actual positioning of the workpiece is less than the number of degrees of freedom that must be limited according to the processing requirements of the process. As a result of under positioning, the degree of freedom that should be limited is not limited, thus the machining requirements cannot be guaranteed. ④ Over positioning. When the workpiece is positioned, if two or more positioning support points repeatedly limit the same degree of freedom on the workpiece, it is called over positioning. Over positioning will lead to interference between positioning support points which limit the same degree of freedom repeatedly, which will lead to instability of positioning and damage of positioning accuracy. In practice, over positioning is not necessary to avoid. Sometimes because of the need to strengthen the rigidity of the workpiece, or for special reasons, it is necessary to use more positioning elements than six supporting points, or adopt auxiliary movable support points. |