|

|

Mechanical engineer should master all kinds of machine tool knowledge!A good mechanical process engineer, must be a good processing equipment application engineer, all kinds of knowledge of the mechanical industry are skilled. A good mechanical process engineer must be a good processing equipment application engineer. He has a very accurate and full understanding of the types, application scope, structural characteristics and processing accuracy of various processing equipment in the mechanical industry. At the same time, he can also combine the specific situation of his own company's equipment to make reasonable processing parts and processing procedures The equipment layout and arrangement, understand their own processing advantages, also know their own processing disadvantages, can be very good to develop strengths and avoid weaknesses to coordinate the company's machining work. Now, we do a general analysis and understanding of several processing equipment commonly used in the mechanical processing industry, so that we can have a relatively clear and clear definition of the processing equipment in this industry from the perceptual point of view. At the same time, we can analyze various processing equipment theoretically, so as to better combine the practice in the future work, so as to make progress Guide our work step by step and help our work. Our introduction focuses on the most common machining equipment in the mechanical processing industry, such as turning, milling, planing, grinding, boring, drilling, wire cutting and other processing equipment, and makes a further detailed elaboration on the types, application scope, structural characteristics and processing accuracy of these processing equipment. 1. Lathe Type of lathe There are many types of lathes. According to the statistics of a machining technologist's manual, there are 77 kinds of lathes. The typical ones are: instrument lathes, single shaft automatic lathes, multi axis automatic or semi-automatic lathes, return wheel or turret lathes, crankshaft and camshaft lathes, vertical lathes, floor and horizontal lathes, profiling and multi cutter lathes, axle roller spindles and spading lathes, etc For many small classification, the number varies, and in our machinery industry is more commonly used vertical lathes and horizontal lathes, almost machining places can see the figure of these two lathes. Applicable range of lathe processing We mainly choose several typical lathe types to introduce the application range of machining. A. Horizontal lathe is suitable for turning internal and external cylindrical surface, conical surface, forming rotary surface and annular groove, turning cross section and various threads, and can be used for drilling, reaming, reaming, tapping, threading and knurling. Although the ordinary horizontal lathe has a low degree of automation and more auxiliary time in the processing process, because of its wide processing range and good general performance, this type of machine tool has been widely used and popularized in the mechanical processing industry. It is one of the typical representative processing equipment in our machinery industry, and also an indispensable processing equipment in the mechanical processing industry One. B. Vertical lathe is suitable for machining various kinds of frame and shell parts, as well as internal and external cylindrical surface, conical surface, end face, groove, cutting, drilling, expanding and reaming of various parts. With the aid of additional devices, it can also realize the processing procedures of turning thread, turning end face, copying, milling and grinding. Machining accuracy of lathe A. The machining accuracy of common horizontal lathe is as follows: Roundness: 0.015mm; cylindricity: 0.02/150 mm; flatness: 0.02 / & cent; 150 mm; surface roughness: 1.6 RA / ¦Ì M. B. The machining accuracy of vertical lathe is as follows: Roundness: 0.02mm; cylindricity: 0.01mm; flatness: 0.03mm. The above machining accuracy is only a relative reference value, which does not mean that all lathes meet the requirements. Many lathe equipment have certain up and down floating amount according to the specific requirements of the manufacturer and the specific situation of assembly. However, no matter how large the floating amount is, the machining accuracy value must meet the requirements of the national standard for such equipment. If the equipment is purchased, it will be increased If the accuracy requirement fails to meet the requirements of national standard, the purchaser has the right to refuse acceptance and payment. 2. Milling machine

There are more than 70 types of milling machines according to the statistics of a machining technologist's manual. The typical categories are: instrument milling machines, cantilever and ram milling machines, gantry milling machines, plane milling machines, profiling milling machines, vertical lifting platform milling machines, horizontal lifting platform milling machines, bed milling machines, tool milling machines, etc., which are divided into many small categories, and the number is different Vertical machining center and gantry machining center are commonly used in our machinery industry. These two types of milling machines can be seen in almost mechanical processing places. We also make a general introduction and analysis for these two typical milling machines. Application scope of milling machine Because there are too many types and structures of milling machines, and the application of a wide range of differences, so we point to the most commonly used vertical machining center and gantry machining center two typical milling machine to do a processing range. A. Vertical machining center (as shown in the figure above). The vertical machining center is actually a vertical CNC milling machine with a tool library. Its main feature is that it uses multi edge rotary cutter for cutting, and can process plane, groove, tooth splitting parts, spiral surface and various curved surfaces. Especially with the application of numerical control technology, the processing range of this type of machine tool has been greatly improved, In addition to a variety of milling operations, it can also drill, boring, reaming, tapping and other composite processing of the workpiece, which has a very broad practical and universal significance. B. Gantry machining center, compared with vertical machining center, gantry machining center is the compound application of CNC gantry milling machine plus tool magazine. In terms of processing range, gantry machining center has almost all the processing capacity of ordinary vertical machining center, and can adapt to the processing of larger tools in the shape and size of parts, and also has very large processing efficiency and precision Especially the practical application of five axis linkage gantry machining center, its processing range has also been greatly improved, which laid the foundation for the development of China's manufacturing industry to the high-end direction. Machining accuracy of milling machine: A. Vertical machining center: Flatness: 0.025/300 mm; coarseness: 1.6 RA / ¦Ì M. B. Gantry machining center: Flatness: 0.025/300 mm; coarseness: 2.5 RA / ¦Ì M. The above machining accuracy is only a relative reference value, which does not mean that all milling machines meet the requirements. Many milling machines have a certain up and down floating amount according to the specific requirements of the manufacturer and the specific assembly conditions. However, no matter how large the floating amount is, the machining accuracy value must meet the requirements of the national standard for such equipment. If the equipment is purchased, it will be increased If the accuracy requirement fails to meet the requirements of national standard, the purchaser has the right to refuse acceptance and payment. 3. Planer

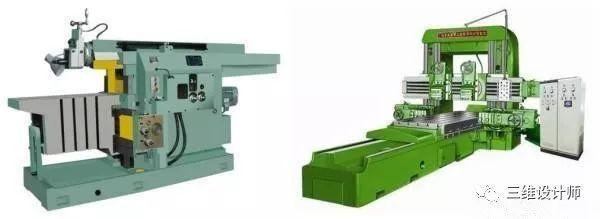

Compared with lathes and milling machines, the types of planers are much less. According to the statistics in the manual of mechanical processing technologists, there are about 21 kinds of planers. The typical types are: cantilever planer, gantry planer, shaper, edge and mold planer. These categories are divided into many small types of planer products, and we have the highest utilization rate and the widest popularity rate in the machinery industry Should be a shaper and planer, as shown in the above figure, we will do a basic analysis and introduction for these two typical planers. Application scope of planer The planing motion of planer is mainly the cycle and straight-line movement relative to the processing workpiece. The applicable planing part features are plane, inclined plane and concave convex surface, and can also be planed for various curved surfaces. However, due to the limitations of its own processing characteristics, the speed of planing is not too high, and the planer with return stroke does not participate in the machining and cutting of parts As a result, the processing efficiency is relatively low. At the same time, with the great technical improvement of CNC and automation of other processing equipment, the planing processing method has been gradually replaced. From the perspective of many equipment upgrading trends, this type of machining machine tool has not been greatly upgraded and innovated. To a large extent, it still stays in the original structure and layout, especially the vertical machining center With the vigorous development of Longmen machining center and the continuous innovation of machining tools, the planing machine's processing advantage has been greatly replaced in the processing range, which makes the equipment with relatively low processing efficiency in a very awkward situation. Machining accuracy of planer Planing machining accuracy can generally reach the accuracy level of it10-it7, especially for the machining of long guide rail surface of some large machine tools, and even can replace grinding processing, which is the so-called "precision planing instead of fine grinding" machining method. 4. Grinder

Types of grinding machines Compared with the former several types of processing equipment, there are more types of grinders. According to the statistics of a machining technician's manual, there are about 194 kinds of grinders, which can be divided into: instrument grinder, cylindrical grinder, internal grinder, grinding machine, coordinate grinder, guide rail grinder, cutter edge grinder, plane and end face grinder, crankshaft camshaft spline and roller grinder, tool grinding machine Machine, superfinishing machine, inner honing machine, outer circle and other honing machines, polishing machines, abrasive belt polishing and grinding machine tools. There are many types of grinding machines, such as cutting tool grinding and grinding machine, indexable blade grinding machine, grinding machine, ball bearing ring groove grinding machine, roller bearing ring raceway grinding machine, bearing ring superfinishing machine, blade grinding machine, roller machining machine, steel ball processing machine, valve piston and piston ring grinding machine, automobile and tractor grinding machine, because the classification and classification of grinder should be too wide, And many grinders are specific equipment in specific industries, so we point to the general use of the grinder in the mechanical industry to do a basic introduction, in this article, we mainly choose cylindrical grinder and surface grinder to do a brief description. Applicable range of grinding machine A. Cylindrical grinder and cylindrical grinder are mainly used to process cylindrical surface, conical surface or the outer surface of other revolving body and shoulder end face. Because of their good processing adaptability and processing accuracy, they are widely used in the machining of some high-precision parts, especially in the final finishing process of these parts, which can not only guarantee the processing to the maximum extent The geometric size of parts can also achieve better surface finish requirements, so it is one of the indispensable equipment in the machining process. B. Surface grinder, which is mainly used to process the surface of parts such as plane, step surface and side, is also widely used in the mechanical industry, especially in the processing of some high-precision parts surface, the grinder is almost the last choice to ensure the processing accuracy. Because of this, the use of surface grinder is a required course for most grinding operators, even in some equipment installation In the matching industry, the use of surface grinder is also the standard skill of assembly personnel, because the grinding work of various adjustment pads in the assembly process depends on the surface grinder. Machining accuracy of grinder A. Machining accuracy of cylindrical grinder: Roundness and cylindricity: 0.003mm; surface roughness: 0.32ra/¦Ì M. B. Machining accuracy of surface grinder: Parallelism: 0.01/300 mm; surface roughness: 0.8 RA / ¦Ì M. From the above processing accuracy, we can also clearly see that compared with the previous lathe, milling machine, planer and other processing equipment, grinder can achieve higher behavior tolerance accuracy and surface roughness, so in the finishing process of many parts, grinder is widely used. 5. Boring machine

Types of boring machines Compared with the previous several types of processing equipment, boring machine also belongs to a relatively small number of processing equipment. According to the statistics of a machining technologist's manual, there are about 23 kinds, which can be divided into the following categories: deep hole boring machine, coordinate boring machine, vertical boring machine, horizontal milling boring machine, precision boring machine, boring machine for automobile and tractor repair, etc., which is the most common in our machinery industry The most commonly used boring machine should be flying coordinate boring machine, the following we also do a brief introduction and analysis of some characteristics of the coordinate boring machine. Applicable range of boring machine There are various types of boring machines. We will give a brief introduction to the coordinate boring machines. You can learn other types of boring machines by analogy. The coordinate boring machine is a kind of precision machine tool with precise coordinate positioning device. It is mainly used for boring holes with high requirements of size, shape and position accuracy. It can be used for drilling, reaming, reaming, end face cutting and grooving It can also be used for coordinate measurement, precise calibration and marking. It has a wide range of reliable processing characteristics. However, with the vigorous development of CNC technology, especially the development of CNC vertical milling machine and CNC horizontal milling machine, boring machine, once the overlord of hole system processing equipment, is also in danger of being replaced. Of course, it also has an irreplaceable objective side. However, no matter what the extinction or development of equipment, it is a kind of progress and technical for the mechanical processing industry Progress is not only the progress of technology, but also the progress of our country's manufacturing industry. Machining accuracy of boring machine The hole diameter accuracy of coordinate boring machine is generally it6-7, and the surface roughness is 0.4-0.8ra/¦Ì M. But the boring machine processing has a very bad place, especially in the processing of cast iron parts, it is called a dirty, a white faced boy walks in, a Zhang Fei Li Kui jumps out, there is a feeling that the boring machine is completely different after starting the boring machine. Therefore, based on the practical reasons of such a processing link, the possibility of this equipment being replaced in the future is also increasing, because who is not there What about your appearance? As soon as possible, many people do not, but we also need to pretend that we have a lot of appearance. 6. Drilling machine

Types of drilling machines This is the most widely used processing equipment in the machinery industry. If a machining factory does not have one, you are sorry to say that you are dry processing. According to the statistics of a machining technologist's manual, there are about 38 kinds of processing equipment, which can be divided into the following categories: coordinate boring drilling machine, deep hole drilling machine, radial drilling machine Table drilling machine, vertical drilling machine, horizontal drilling machine, milling drilling machine, central hole drilling machine, etc., and the most commonly used in the mechanical industry is the radial drilling machine. It is only the standard configuration of our mechanical processing industry. Without this equipment, you can't do this industry. For this reason, we will focus on introducing this kind of drilling machine. Application scope of drilling machine We are mainly talking about the rocker arm drill. For this kind of machine tool, I have only one sentence here, that is, drilling various types of holes. In addition to drilling, we can also realize reaming, reaming, reaming, tapping and other processing procedures. However, there is a big problem, that is, the positioning accuracy of the hole system is not high. Therefore, we usually do not choose parts with high accuracy of hole series position Drilling machine. Machining accuracy of drilling machine Because basically there is no machining accuracy to speak of, just drill a hole. 7. Wire cutting

As for the wire cutting processing equipment, I have not been exposed to a lot, so I have not accumulated a lot in this respect, and have not done a lot of homework. Therefore, it is limited in the scope of use in the machinery industry, but it also has its unique existence value, especially for the blanking and processing of some special-shaped parts, there are still some relative advantages, but in view of its With the low processing efficiency and the vigorous development of laser machine, WEDM is gradually walking on the edge of the industry which has been eliminated. |