|

Do you understand the basic knowledge of machining methods?In our life, many people may not know much about the machinery industry, but mechanical products are used in all aspects of our life. High tech products such as spaceships, aircraft carriers, ordinary products such as cars, ships, are inseparable from machining. Therefore, today to popularize a little knowledge of machining, interested friends can understand.

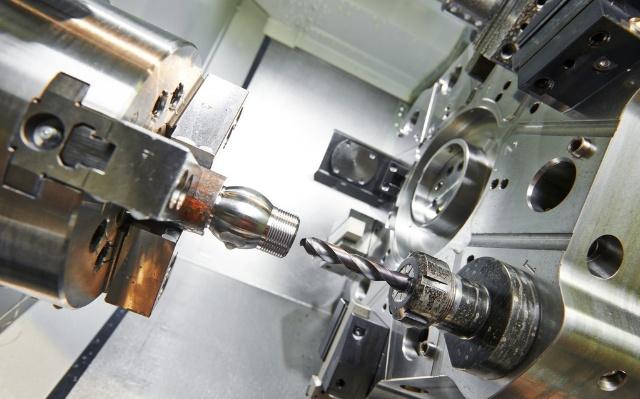

Selection of surface processing method for parts When machining the surface of parts, the corresponding processing methods should be selected according to the processing requirements of these surfaces and the structural characteristics and material properties of the parts. When selecting the processing method of a certain surface, the final processing method is always selected first, and then the processing methods of each related leading operation are selected one by one. 1、 Principle of processing method selection 1. The economic machining precision range of each machining method should be considered in the selected machining method, which should be compatible with the accuracy requirements and surface roughness requirements of the machined surface. 2. The selected machining method can meet the requirements of geometric shape accuracy and mutual position accuracy of machined surfaces. 3. The selected processing method should be compatible with the machinability of the part material. For example: hardened steel, heat-resistant steel and other materials with high hardness should be processed by grinding method. 4. The processing method should be adapted to the production type. In mass production, efficient machine tools and advanced processing methods should be adopted. In single small production, general machine tools and conventional processing methods are mostly used. 5. The selected processing method should be compatible with the existing equipment conditions of the enterprise and the technical level of the workers.

2、 Arrangement of processing sequence The division of processing stages. According to different processing properties and functions, the process can be divided into three stages 1. Rough machining stage. It is mainly to cut off most of the allowance on the machined surface, and the rough machining of the precision datum is completed in the initial process of this stage. 2. Semi finishing stage. Prepare for finish machining of each main surface (meet certain precision requirements and reserve finishing allowance), and finish machining of some secondary surfaces. 3. Finishing stage. Make the main surface meet the specified quality requirements. In addition, there are finishing (superfinishing, mirror grinding, grinding and superfinishing, etc.) or finishing (rolling, polishing, etc.) for some precision parts. The following situations can not be divided into processing stages: parts with low processing quality requirements, or parts with good blank rigidity and high precision, although the processing quality requirements are high, can not be divided into processing stages; especially when machining with machining center, for large and heavy workpieces with not too high processing requirements, rough machining and finish machining are completed in one clamping, and the processing stages are often not divided.

The functions of dividing processing stages are as follows: 1. To avoid the influence of internal stress redistribution on the machining accuracy. 2. The influence of elastic deformation and thermal deformation caused by large clamping force and cutting force on finish machining is avoided. 3. By separating the rough and finish machining stages, the defects of the blank can be found in time and the unnecessary loss can be avoided. 4. The machine tool can be used reasonably to keep its precision for a long time. 5. To meet the needs of heat treatment arrangement in the process of processing. |